Bulk Tube Sorter

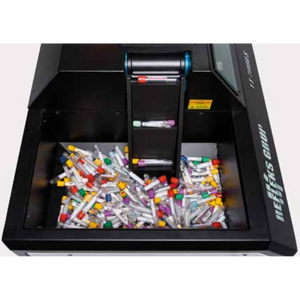

Easy and continuous sample loading in bulk, with a hopper capacity of up to 800 tubes. Connection to TT Smartline for reception also possible. It is compatible with all standard tubes of 8-22mm diameter & 70-120mm length.

Sample tubes are registered via the barcode scanner for quick and dependable identification.

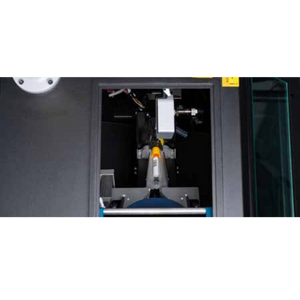

Throughput of 2000 tubes/hr. It has 12 target bins +1 error bin by default and can be configured from 6 to 18 target bins. Sample tubes are continuously sorted and carried into assigned target bins. Optionally, it can connect to the TT Smartline conveyor system. The user can draw out any target bin anytime, and the process does not stop. Sorting continues without interruptions by assigning a matching target bin for the removed one; hence the throughput performance is guaranteed. This “Refleks Mode” feature can be cancelled on the screen menu if needed. Unidentifiable and mismatched sample tubes go in the error bin. It can sort the recapped sample tubes for archiving purposes.

It has a color touchscreen with a user-friendly multilingual interface (English & Turkish by default – other languages by option). The operating system uses Industrial PC Windows 10 Pro. Its reporting feature, independent of LIS, provides various reports.

Smart Conveyor System

Recap & Archive

Recapper

Stand-alone Decapper

Smart Bulk Tube Sorter

You can use this form to send us any questions, suggestions or requests. Please fill in the required information completely so that we can get back to you as soon as possible. Our customer satisfaction-oriented team is always at your side and ready to solve your questions.